Find ideas for your next trip to New York

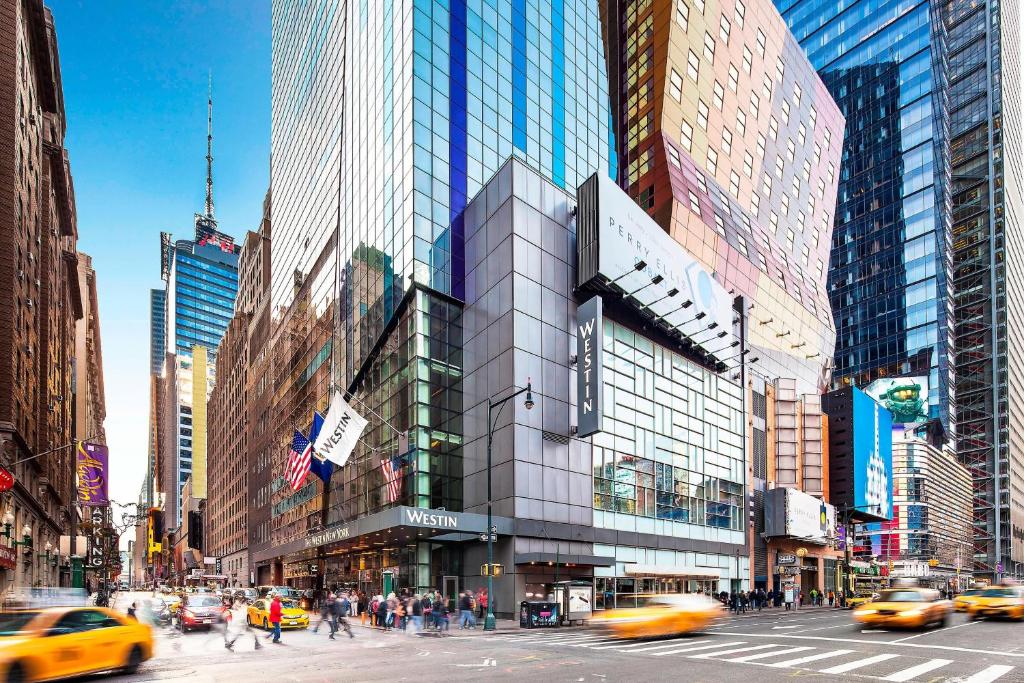

In a 5 star hotel, you will find the most prestigious resort or the most beautiful 5 star hotel in New YorkThe most luxurious apartments to enjoy your stay alone, with family, with friends or as a couple in the wonderful city of American, you have the possibility to choose your favorite hotel that will allow you to fully enjoy your stay after a day of walking through the streets of this city: relaxing, romantic to go with that special person, hotels with great luxury, reserved for adults, all inclusive, hotels with entertainment programs for the whole family ...

Other destination ideas than New York